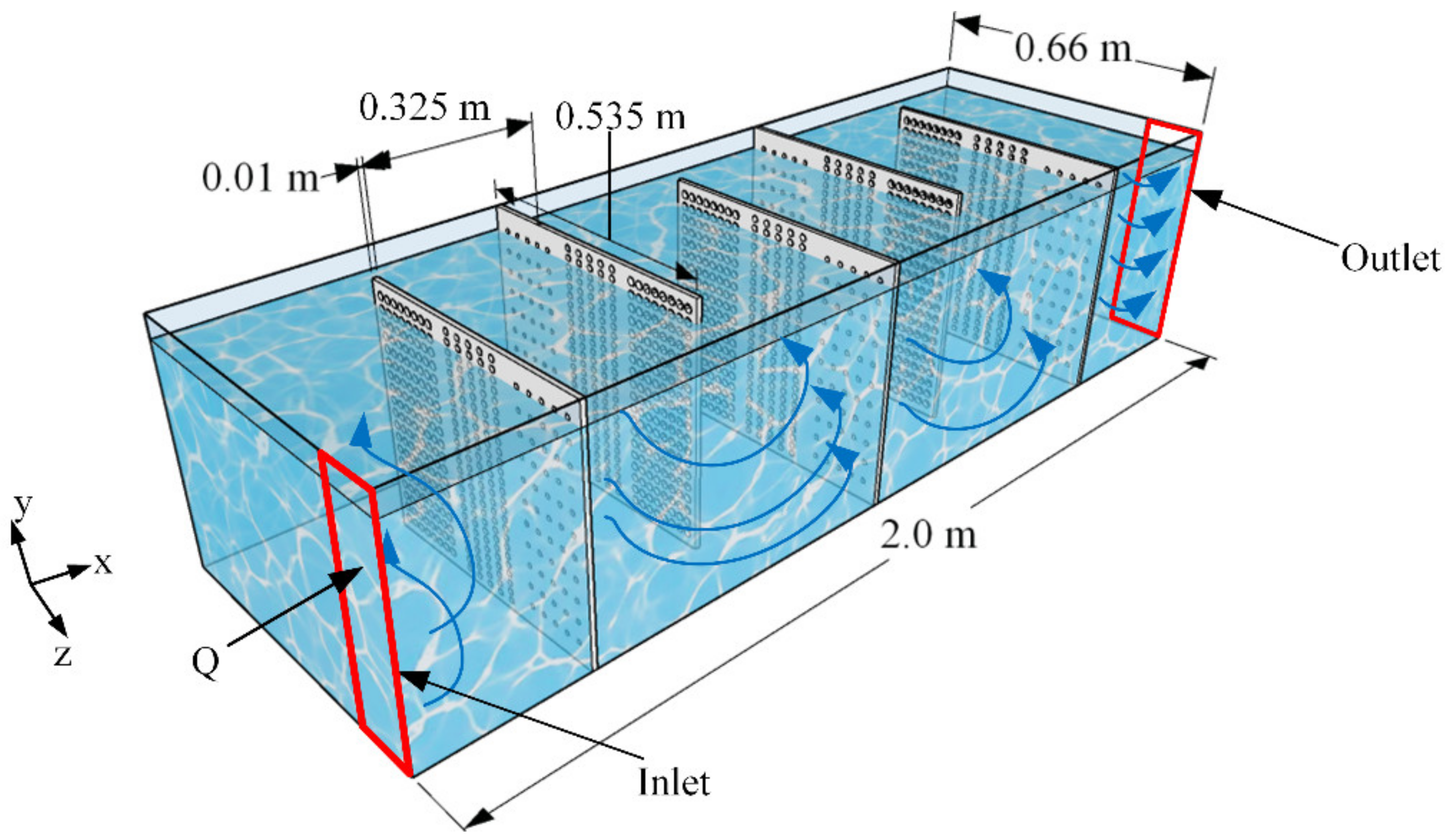

At the end opposite the return there were 2 15 dia holes Hlocated about 3 and 6 from the bottom. Hydraulic system design considerations.

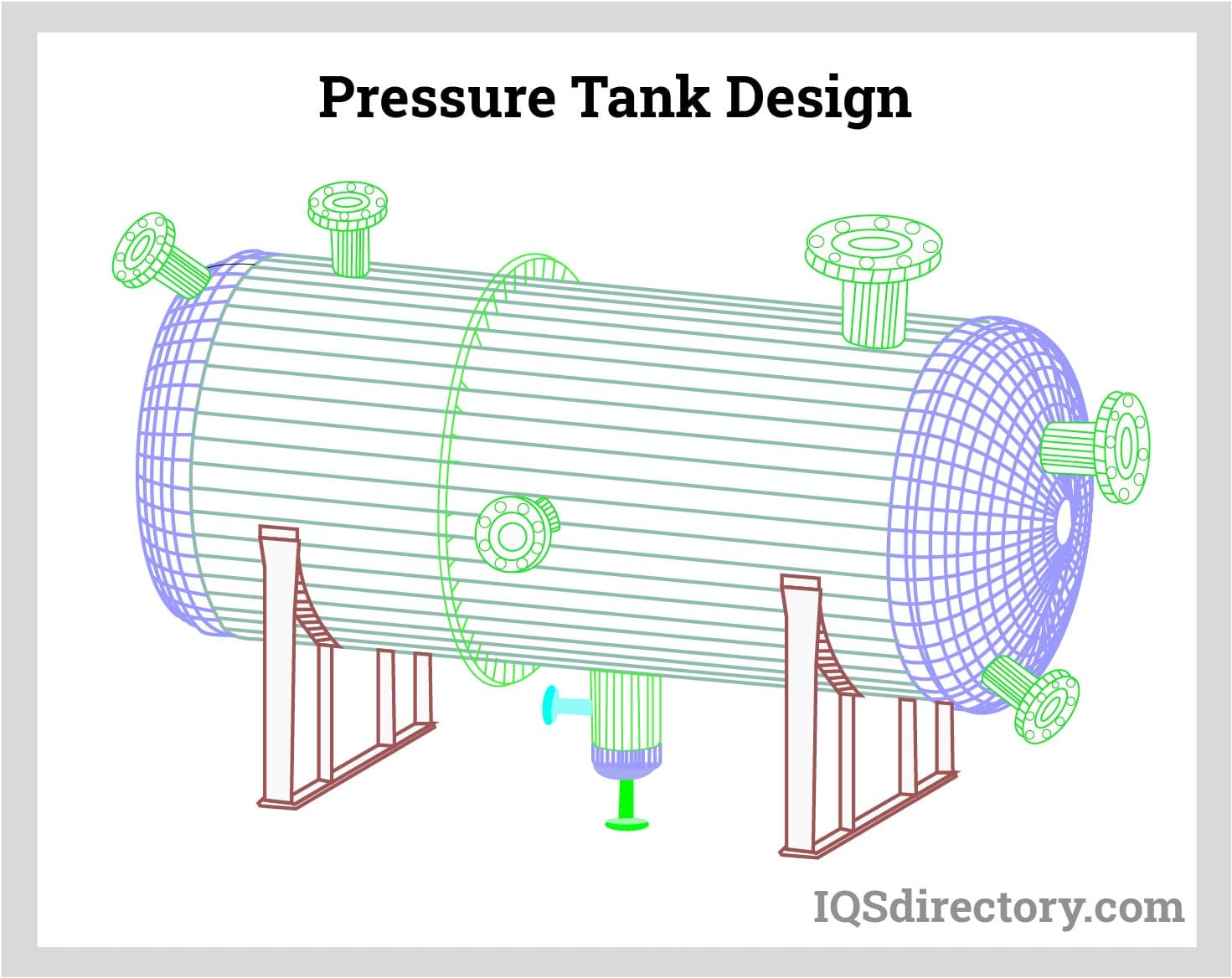

Pressure Tanks Types Applications Benefits And Things To Consider

Richer Mix are employed - M20 M30.

. 1 the tank must have a large enough volume. The bending and tension stress value is kept within the permissible value in order to prevent cracking. In addition some systems that have proportional or servo valves may also be highly sensitive especially to fluid contaminants.

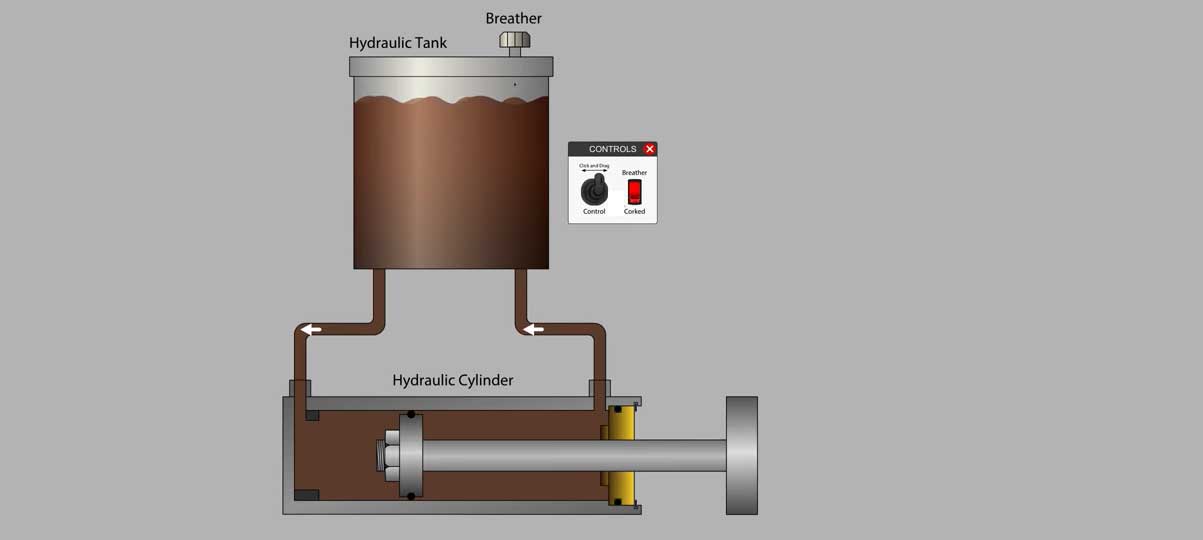

Hydraulic oil spends most of its time in the reservoir and as such various tank design criteria provide benefits for the hydraulic system as a whole. The most susceptible components in any hydraulic system are the pump motors and cylinders. The drain D was dead center in the V- bottom.

The important considerations in the design of water tank is as per IS. When designing the optimum hydraulic reservoir most of the considerations are in keeping the oil clean and cool. The primary function of the reservoir is the temporary storage of hydraulic fluid.

Septic tanks for commercial systems are recommended to have at least three days of design hydraulic retention time with four-plus days for challenging streams. Equalization is the primary purpose for constructing water distribution storage tanks. In accordance with ISO 14121-1 a risk assessment must be conducted to ensure there are not any predictable risks in the design that could carry over into the field.

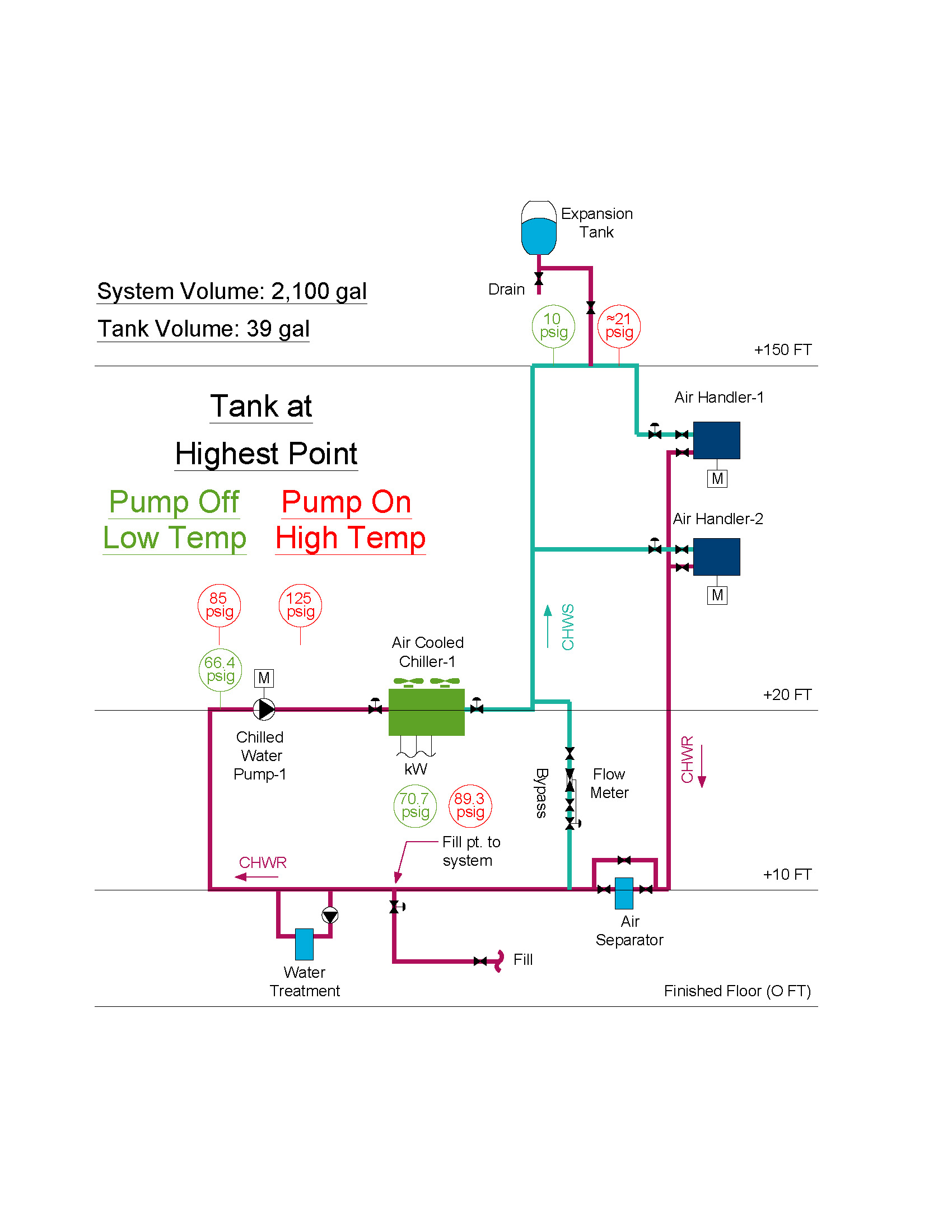

There are several key considerations in the hydraulic design of water storage tanks. N Energy dissipated due to friction and turbulence during pump operation Major Losses Friction Losses Due to friction between pumped water and inner surface of piping H f 302 L D-1167 VC h185 Hazen-Williams Formula where. Below are common tanks with design considerations related to managing commercial flows.

Flexible tanks must be able to withstand all types of conditions from extreme heat to extreme cold. Under extreme cold some materials can become stiff or brittle. Reasonably foreseeable misuse shall not cause hazards.

Hydraulic Tank Design Considerations. Have no idea what youre asking OK ok. FUNCTIONS OF A HYDRAULIC TANK A hydraulic tank is an important part of a hydraulic power unit and represents the heart of the hydraulic system.

Hydraulic System Design Operation. When designing the optimum hydraulic reservoir most of the considerations are in keeping the oil clean and cool. Surge Tank Design Considerations for.

The most susceptible components in any hydraulic system are the pump motors and cylinders. On the one hand as far as possible to meet the requirements of heat dissipation on the other hand when the hydraulic system stops working it should be able to accommodate all the working medium in the system. The drain D was dead center in the V- bottom.

An important aspect of pump hydraulic system design is the suction or inlet conditions. The advantage of using simulation techniques in the field of hydraulic tank design will be explained by illustrating the results of on-going research tasks. Disregard for proper allowances can result in vortices cavitation and loss of prime.

3370-2009 Part - II. TPU-coated nylon or polyester made by Erez keeps its flexibility even under the harshest conditions. The following points should be considered when designing the fuel tank.

Materials Science and Engineering PAPER OPEN ACCESS Design of an optimal hydraulic tank configuration To cite this article. In this chapter the word tanks will be used to describe treated water-storage facilities although the term reservoirs is preferred by some whereas others use the word reservoir to describe only ground-level and buried tanks The key considerations in the hydraulic design of water storage tanks are described in the following sections. Here are some important points to consider in designing and using hydraulic systems.

High Water Tightness have to be provided. From very large and generally stationary industrial units through too much smaller and compact packs designed for mobile applications. Over sizing the reservoir by 5 to 15 gallons will.

This way the aerated oil stayed toward the top any particles that bypassed the filter stayed on the inlet side. Hydraulic tank design is often neglected part of the development. Read customer reviews find best sellers.

The baffle ran the length of the v-bottom tank slightly offset from the center. 3 Resistance to Cold and Hydrolysis. Hydraulic Tank Design Considerations.

L is length of pipe feet D is diameter of pipe square feet V is mean velocity fps C h is Hazen-Williams friction coefficient. Hydraulic Powerpack Design Considerations Hydraulic power packs are the very heart of your hydraulic circuit so they need to be designed correctly. Design of modern hydraulic tank using fluid flow simulation.

ــــــــــــــــــــــــــــــــــــSurge Tank Design Considerations for Controlling Water. The challenges of mobile reservoir design. More retention time is likely needed for systems with grinder pumps or with large amounts of.

Surge Tank Design Considerations for Controlling Water. Ive passed this thing several times because I thought it was a silly question but then I thought about it some. Never undersize the reservoir.

Over sizing the reservoir by 5 to 15 gallons will offer substantial benefits by allowing the. In this chapter the word tanks will be used to describe treated water-storage facilities although the term reservoirs is preferred by some whereas others use the word reservoir to describe only ground-level and buried tanks The key considerations in the hydraulic design of water storage tanks are described in the following sections. The excess reserve oil in a hydraulic system is to dissipate heat and prolong the life of the pump.

Hydraulic power packs come in many different shapes and sizes. 60 Litre Hydraulic Oil Tank from recoveryandwinchie. At an absolute minimum the additional analysis of the 1 AEP discharge is required for both the existing and the proposed conditions.

5- Closed surge tank. In addition some systems that have proportional or servo valves may also be highly sensitive especially to fluid contaminants. Now I dont pretend that this answer is exhaustive I still think the answer is wasting time but the designer in me says.

In addition some systems that have proportional or servo valves may also be highly sensitive especially to fluid contaminants. A rule of thumb for sizing a hydraulic reservoir suggests that its volume should equal three times the rated output of the systems fixed-displacement. October 20 2014 By Josh Cosford.

Int J Simulat Model. Hydraulic system designs for heavy equipment and other machinery must take into account how and where the system is to be used. An overall hydraulic performance curve for the designed culvert indicates headwater and outlet velocity characteristics for the entire range of discharges.

Troubleshooting Hydraulic Reservoirs Breathers And Filters

Hydraulic Reservoir Design Considerations

Parts Of A Toilet And How It Works 3 Full Diagrams Homenish

Hydraulic Reservoir Design Considerations

Water Free Full Text A Perforated Baffle Design To Improve Mixing In Contact Tanks Html

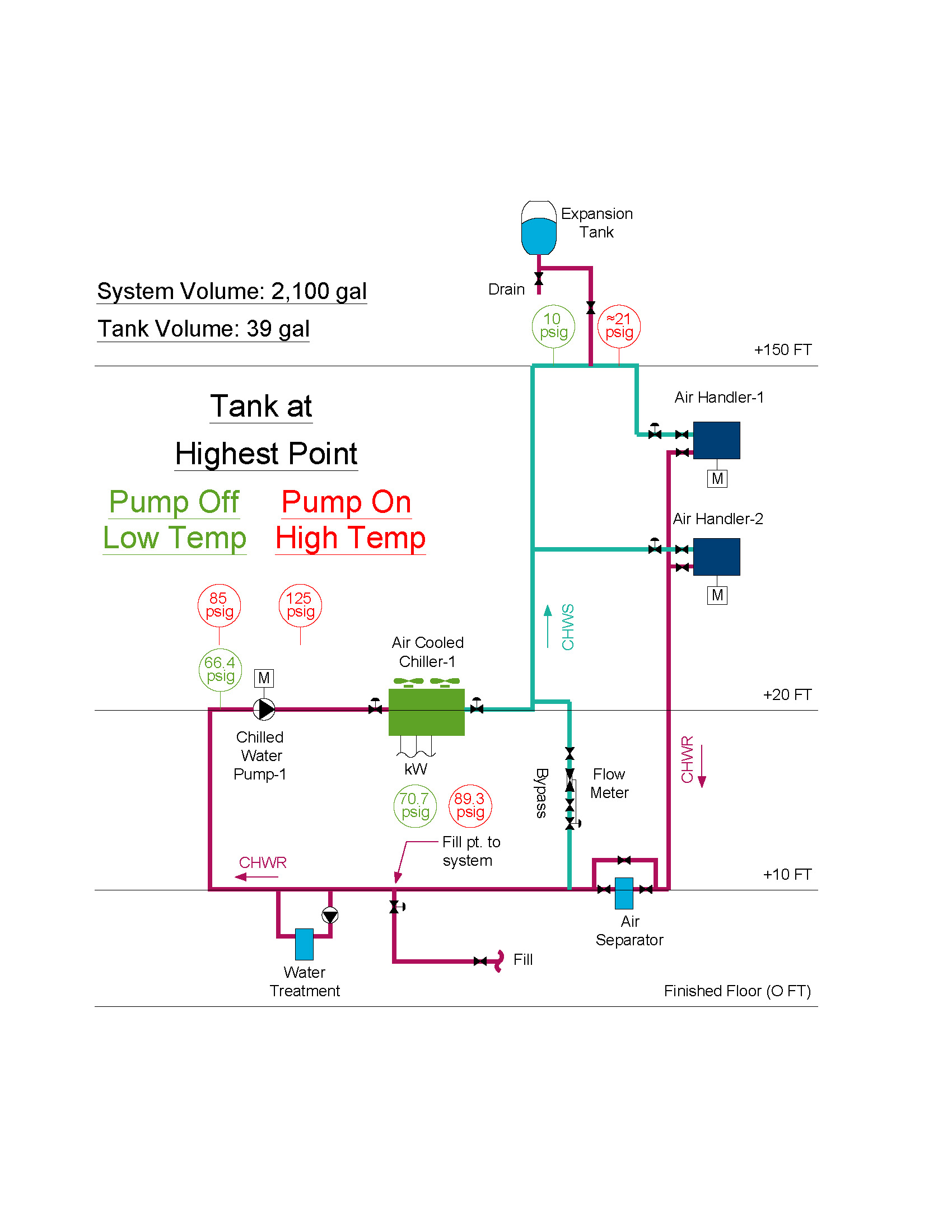

Expansion Tank Design Guide How To Size And Select An Expansion Tank For A Chilled Water System

Hydraulic Reservoir Design Considerations

Are You Using The Right Tank Design For Your Industrial Mixing Application Part 3 Proquip Inc Mixing Solutions

0 comments

Post a Comment